- Home

- Dai Viet Introdution

- PRODUCTS

- Typical Projects

- Services

- News

- contact

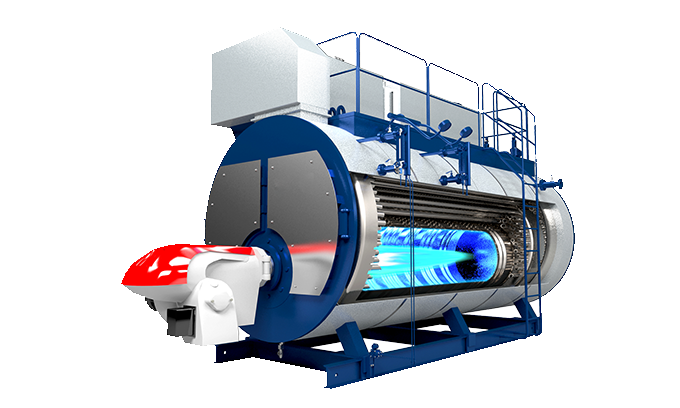

DAI VIET vertical oil/gas fired boiler

Code:Dai Viet vertical oil-fired gas boiler The boiler is a water-tube boiler. Oil/gas combines with air and burns inside the combustion chamber to produce high-temperature combustion products (smoke).

DAI VIET OIL & GAS STEAM BOILER VERTICAL TYPE

Introduction of oil/gas steam boiler type vertical.

Oil/gas steam boiler DAVITECCO type vertical is a water-tube boiler. Oil/gas combines with the air and burns inside the combustion chamber to create a high temperature combustion product (smoke), smoke moving from the center of combustion chamer to move through multiple passes to heat to the water inside the pipe to generating steam, then smoke reduces the temperature and goes into the chimney to discharge it into the environment. Because the smoke moves through multiple passes, the exhaust smoke temperature is low from 165 to 1800C (at a working pressure of 0.6 Mpa) and the boiler efficiency is high, from 89 to 95%.

Vertical boilers often have very small and small capacities from 100 kg/h to 2000 kg/h. Boilers are compact in design, so it saves space, easy to install, maintain and repair. The time of steam generation reaches the operating parameters quickly so it saves fuel.

Advantages of oil/gas steam boiler type vertical

1. Safety and reliable: with a safety valve, pressure controller, water level control protector, double counter-current and exhaust thermal protective device, multiple chain protection device.

2. Good quality: Boiler has a long working time, stable operation and low noise.

3. Quickly startup, achieving high temperature and pressure in short time.

4. Small installing area: Vertical type, easy to install maintenance and repair, replacement.

5. Environmental protect: the boiler has the function of dust removal, exhaust smoke meets the national environmental standards requirements.

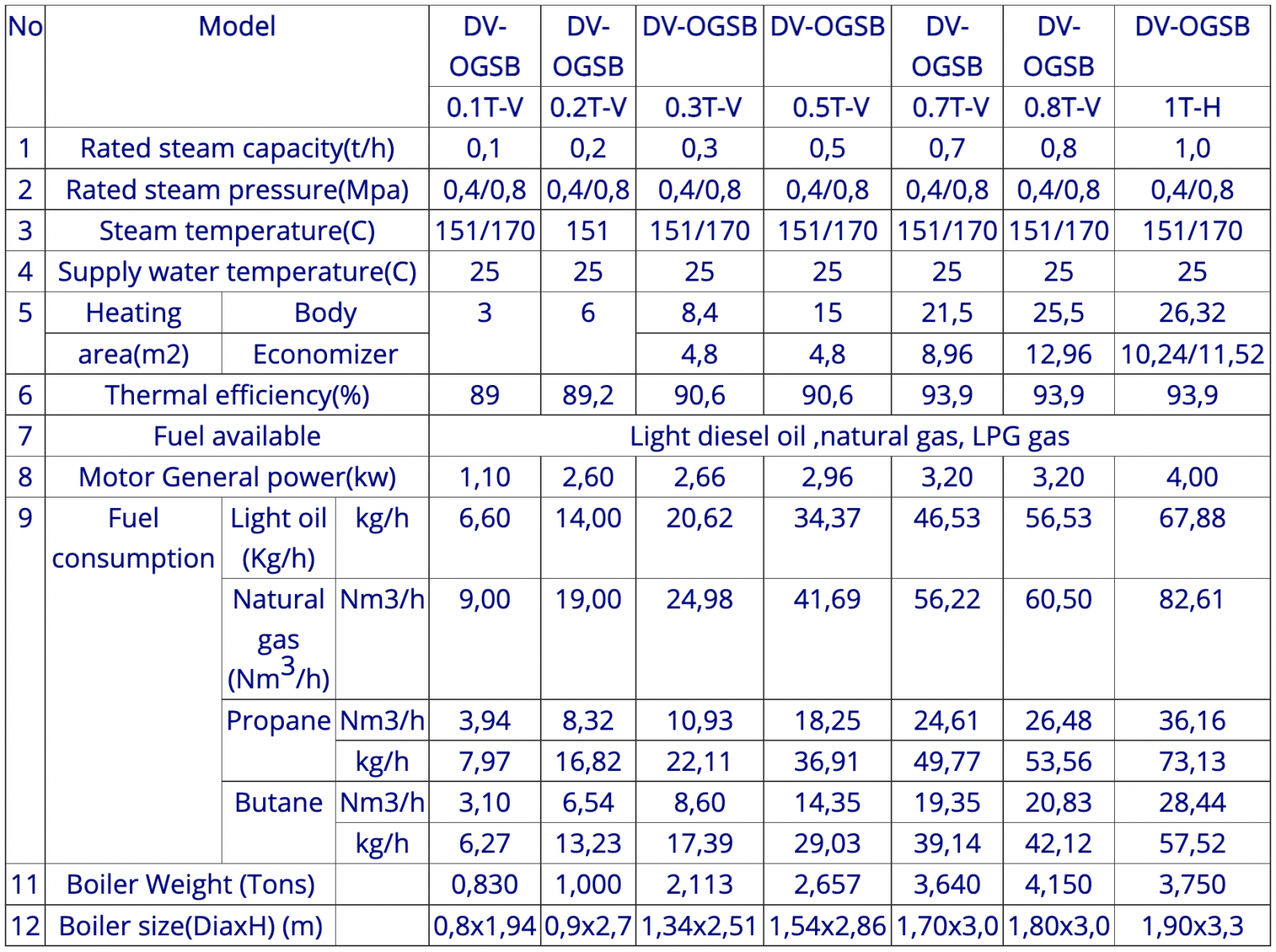

Technical Parameters of steam boiler type vertical:

Notes:

1. The parameter is for reference only, if any changes should follow the actual drawing.

2. Design capacity at the request of the customer.

Transaction Process

Customer Inquiry ® Offer Professional Consulting Service ® Place Order -- Customize Boiler Based on Customers’ needs ® Production-manufacturing ® Testing and handover ® Payment ® Impeccable After Sale Service (installation and debugging, periodic maintenance, etc.)

Offered Technical Documents

.jpg)

1. Installment and Operation Instruction

2. Inspection Certificate of Boiler Quality

3. Foundation Drawing of boiler

4. Boiler Room Design Drawing

5. Quality Certificate

6. Boiler Body Drawing

7. Electric circuit diagram

8. Drawing of valves, pipes and accessories

Contact information :

- DAI VIET TRADING & TECHNICAL SERVICSE COMPANY.,LTD

- Address : 563 NÚI THÀNH STREET – VIET NAM

- TEL : 0983615226/0916860231/(+84)2363.615226

- Web1 : www. Davitecco.com

- Web2 : www. Davitecco.vn

- Email : Info@davitecco.com