- Home

- Dai Viet Introdution

- PRODUCTS

- Typical Projects

- Services

- News

- contact

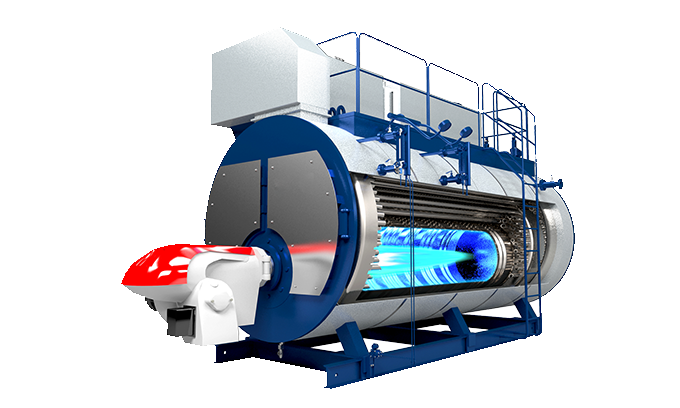

Horizontal Gas/ Oil Steam Boiler Dai Viet

Code: DV-OGSBDai Viet horizontal oil-fired boiler is beautifully designed with equipment and materials selected from famous brands with strict inspection process.

DAI VIET OIL & GAS HORIZIONTAL DAI VIET STEAM BOILER

INTRODUCTION OF GAS/OIL STEAM BOILER TYPE HORIZIONTAL- 3PASS

.png)

Introduction of oil/gas steam boiler type horiziontal - 3 pass

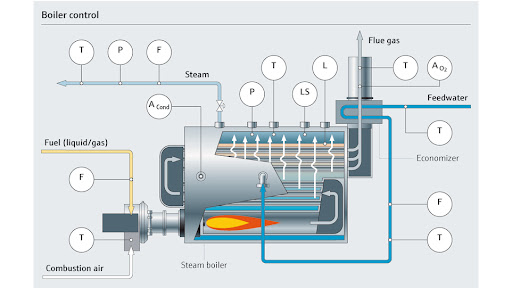

Oil/gas steam boiler DAVITECCO type horizontal – 3 pass is a furnace-tube, fire-tubes boiler. Oil/gas is combined with air and burns inside the furnace tube to create a high temperature combustion product (smoke), after moving out of the furnace-tube pass 1st, the smoke continues to move in the fire-tubes the pass 2nd and pass 3rd to transfer heat for water to generate steam, reduces the smoke temperature, and then go to the chimney and discharge the smoke to the environment. Because smoke moves through three passes, the exhaust smoke temperature is low from 180 to 2000C (at working pressure 1 Mpa) and boiler efficiency is high, from 90 to 95%.

Feature of oil/gas steam boiler

1) New design and advanced technology: DAVITECCO boilers are beautifully design with equipment and materials selected from well-known brands with strict inspection procedures, and apply advanced technology into production, the boiler body is welded by semi-automatic welding machines, so the performance and longevity are high.

2) Burner: The burner is selected Riello burner, which is imported from Italy. Fuel is completely burned and meets strict environmental requirements.

3) Easy maintenance and repair: Boilers are designed for convenient installation, maintenance, repair and replacement.

4) Intelligent control: The boiler can be operated automatically according to the user's installation program.

5) Safe and reliable: Boilers are protected and signaled by many levels: safety valves, pressure relays, temperature controller, protection water level control, alarm and cut off system when incident occur.

Application

Industrial horizontal boilers are widely used for different industrial productions with small capacity requirement, such as textile mill, food & beverage factory, chemical plant, paper processing factory, plastic processing factory, pharmaceutical factory, garment factory, oil refining, shoe making factory, printing plant, school, hotel, swimming pool, laundry, bakery, farm, etc.

Boiler Customization

1) DAVITECCO Boiler owns an mature R&D team and design team, and cooperates with many scientific research organizations for a long time. Customers can choose DAVITECCO boilers based on requirements such as: fuel type, brand and characteristics of burners, water supply pumps, valves and accessories, water treatment systems as well as meeting operational requirements and optimizing the operating efficiency of the boiler.

2) Air Preheater : Boiler system can be equipped with an air preheater, which takes advantage of the heat from high temperature of exhaust smoke to heat the air to improve combustion, save fuel, improve boiler efficiency.

3) Economizer: Boiler system can be equipped with economizer, which takes advantage of the heat from high temperature of exhaust smoke to heat feed water before supplying it to the boiler to speed up steam generation, saving fuel, improving boiler efficiency.

4) Electric control cabinet: Customers can choose to control boiler with traditional electrical equipment or PLC or electronic board with touch screen, in addition they can choose the brand of electrical equipment.

5) Water treatment system: The boiler system is equipped with a water softening system, which helps to improve steam quality, reduce blow down time and build up deposits inside the boiler and increasing working time of the boiler.

6) Exhaust smoke treatment system: The boiler system can install additional exhaust smoke treatment system to treat exhaust smoke that it gets the quality of exhaust air according to the regulations of the Ministry of Natural Resources and Environment.

High Quality Assurance

1) DAVITECCO Boiler owns a team of professional design engineer team. Before production, all design drawings will be approved by boiler experts. The production process is supervised by a team of experienced engineers in the field of boiler manufacturing. Boilers are manufactured when they reach the designed capacity and ensure safety according to Vietnamese standards.

2) To ensure quality assurance, all the materials are used to make the boiler must have a certificate of origin. Qualified materials are put in storage and used for the manufacture of boiler system.

3) To ensure the welding quality, there a professional welding team, including more than 10 senior welders. The welding materials are stored under constant temperature and humidity, to ensure the welding material quality.

4) Nondestructive testing will be done to ensure the welding quality, by using x-ray detection, ultrasonic flaw detection, magnetic test, or penetration test, etc.

5) Hydrostatic testing will be carried out for durable and leak tests of boilers. The test pressure is 1.5 times the design pressure. The testing process is directed by the experts of the pressure equipment testing center. The test results serve as a basis for granting inspection documents for boilers.

Professional Installation and After-sale Team

1) Professional engineer installation team offer the door to door installation and after sale service. The boilers will operate smoothly and safety, and you will get our products without worries.

2) 24 hours hot-line to solve your problems, and offer the professional technical supports and after sale service in time to all over the Viet Nam.

Technical Parameters of steam boiler type horizontal:

.png)