- Home

- Dai Viet Introdution

- PRODUCTS

- Typical Projects

- Services

- News

- contact

Lunt alarm Dai Viet

Code: S000063Fluidized bed boiler is a boiler that uses a fluidized bed type combustion chamber to burn fuel. The fluidized bed combustion chamber provides very good mixing conditions over the entire combustion chamber volume

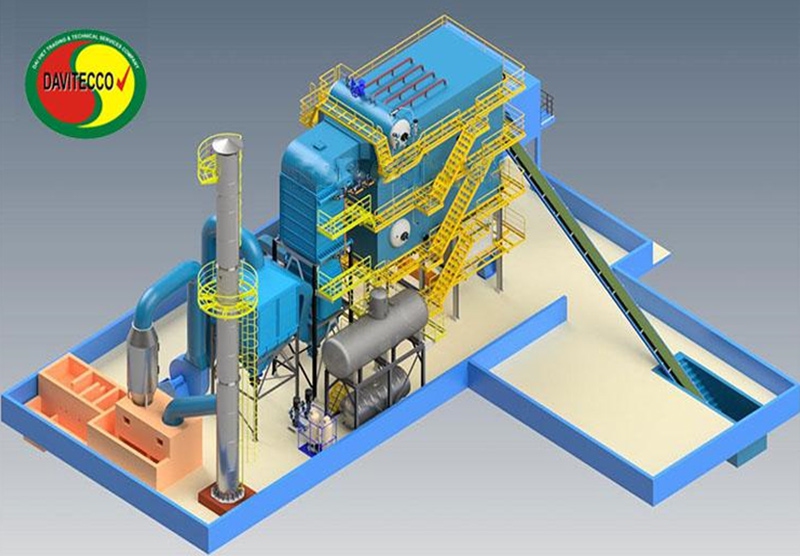

DAI VIET FLUIDZED BED COMBUSTION STEAM BOILER

* INTRODUCTION OF FLUIDZED BED BOILER

Fluidized bed boiler is a boiler that uses a fluidized bed type combustion chamber to burn fuel. The fluidized bed combustion chamber creates very good mixing conditions on the entire volume of the combustion chamber and the combustion temperature of the combustion chamber is not too high, but the fuel will burn out, reducing harmful emissions to the environment.

Fluidized bed boilers can be designed to burn many different types of fuels such as coal, biomass fuel, industrial waste, classified domestic waste, etc.

Fluidized bed boilers designed and manufactured by Dai Viet include:

- Steam generators: like other boilers, fluidized bed boilers have radiant steam generators, convection steam generators, steam sack, and manifolds arranged around and connected to the furnace body forms a natural cycle

- Fuel supply system: automatic or semi-automatic

- Combustion chamber, furnace body

- Water heater, air dryer

- Water softener system and deaerator tank

- Cyclone beam separating dry dust

- Cyclone to separate wet dust

- Level 1&2 air fans

- Exhaust fan and chimney

- System of stairs and working floors

- The furnace wall is built of refractory bricks, refractory concrete and insulated with ceramic and rockwool

FEATURE OF FLUIDZED BED BOILER

1) New design and advanced technology: DAVITECCO boilers are beautifully design with equipment and materials selected from well-known brands with strict inspection procedures, and apply advanced technology into production, the boiler body is welded by semi-automatic welding machines, so the performance and longevity are high.

2) Combustion chamber: Designed to thoroughly burn the fuel and absorb the best heat for steam generation. Including equipment such as: combustion chamber, burner, beams of water pipes surrounding the fire chamber absorbing the heat of the combustion fuel by radiation and convection, a beam of steam-generating tubes, Insulated outside with ceramic and rockwool with reasonable density and thickness, the temperature outside the combustion chamber is not high and reduces heat loss and increases the longevity of the boiler. 3) Recovery unit: including water heater and air dryer used to take advantage of heat from smoke to heat water and air supply to the boiler, increasing the efficiency of the boiler. 4) Dust filtration system: including cyclones separating dry dust, bag dust systems, electrostatic precipitators, combined with cyclones to separate wet dust. These filters will ensure that the smoke of the boiler will satisfy all environmental standards.

5) Easy maintenance and repair: Boilers are designed for convenient installation, maintenance, repair and replacement.

6) Intelligent control: The boiler can be operated automatically according to the user's installation program.

7) Safe and reliable: Boilers are protected and signaled by many levels: safety valves, pressure relays, temperature controller, protection water level control, alarm and cut off system when incident occur.

APPLICATION

Fluidized bed boilers are widely used for various industries with small and medium capacity such as: sugar mills, textile factories, food and beverage factories, chemical plants, paper mills, etc. plastic factory, pharmaceutical factory, etc…

HIGH QUALITY ASSURANCE

1) DAVITECCO Boiler owns a team of professional design engineer team. Before production, all design drawings will be approved by boiler experts. The production process is supervised by a team of experienced engineers in the field of boiler manufacturing. Boilers are manufactured when they reach the designed capacity and ensure safety according to Vietnamese standards.

2) To ensure quality assurance, all the materials are used to make the boiler must have a certificate of origin. Qualified materials are put in storage and used for the manufacture of boiler system.

3) To ensure the welding quality, there a professional welding team, including more than 10 senior welders. The welding materials are stored under constant temperature and humidity, to ensure the welding material quality.

4) Nondestructive testing will be done to ensure the welding quality, by using x-ray detection, ultrasonic flaw detection, magnetic test, or penetration test, etc.

5) Hydrostatic testing will be carried out for durable and leak tests of boilers. The test pressure is 1.5 times the design pressure. The testing process is directed by the experts of the pressure equipment testing center. The test results serve as a basis for granting inspection documents for boilers.

PROFESSIONAL INSTALLATION AND AFTER-SALE TEAM

1) Professional engineer installation team offer the door to door installation and after sale service. The boilers will operate smoothly and safety, and you will get our products without worries.

2) 24 hours hot-line to solve your problems, and offer the professional technical supports and after sale service in time to all over the Viet Nam.

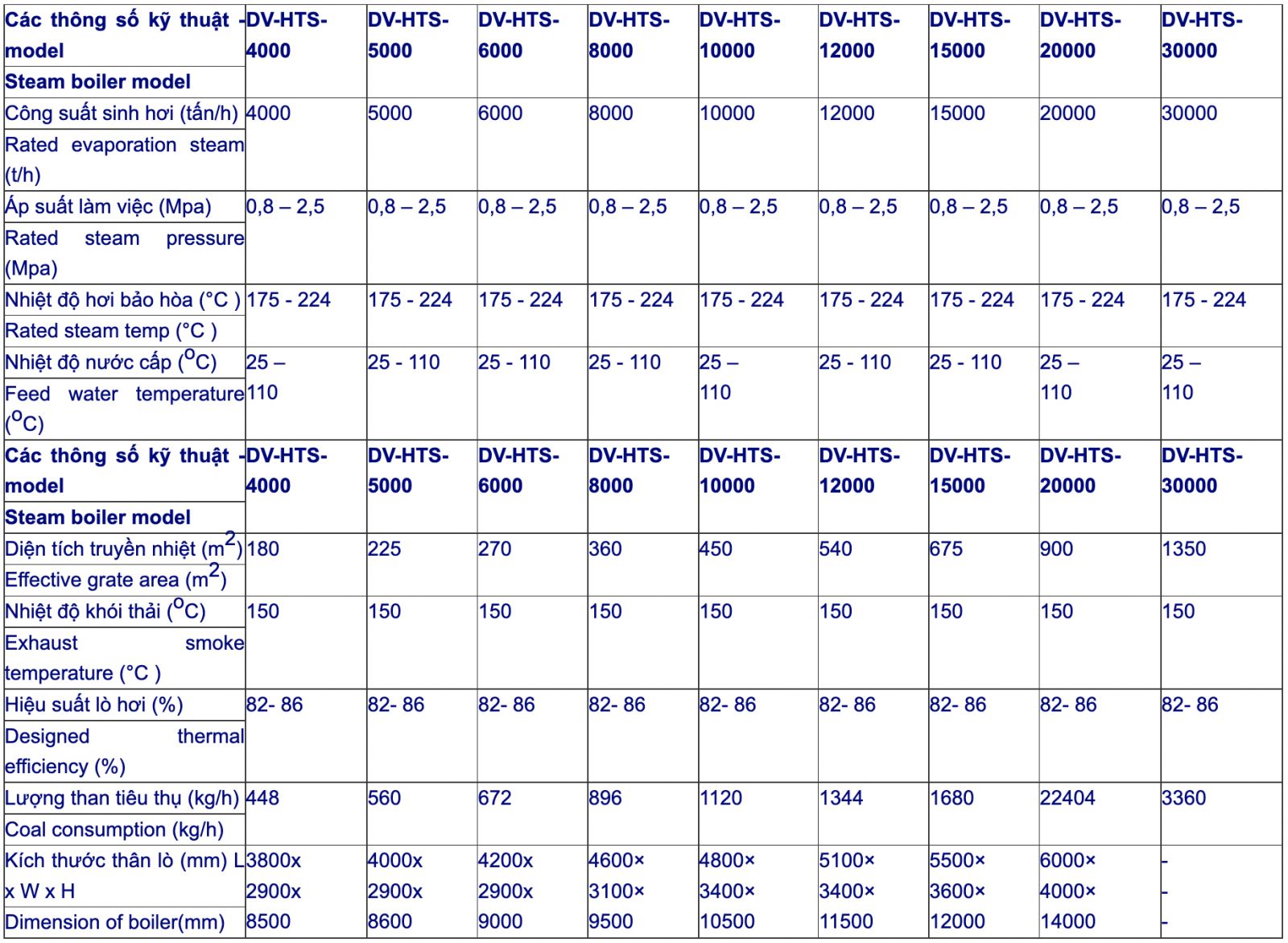

TECHNICAL PARAMETERS OF STEAM BOILER TYPE HORIZONTAL:

Note: Design capacity and fuel or multi fuel at the request of the customers.

TRANSACTION PROCESS

Customer Inquiry ® Offer Professional Consulting Service ® Place Order -- Customize Boiler Based on Customers’ needs ® Production-manufacturing ® Testing and handover ® Payment ® Impeccable After Sale Service (installation and debugging, periodic maintenance, etc.)

|

Offered Technical Documents 1. Installment and Operation Instruction 2. Inspection Certificate of Boiler Quality 3. Foundation Drawing of boiler, dust tank 4. Boiler Room Design Drawing 5. Quality Certificate 6. Boiler Body Drawing 7. Electric circuit diagram 8. Drawing of valves, pipes and accessories |

|

Contact information :

- DAI VIET TRADING & TECHNICAL SERVICSE COMPANY.,LTD

- ADDRESS : 563 NÚI THÀNH STREET – VIET NAM

- TEL : +84.2363.615 226

- Hotline: +84.983 615 226

- WEB : www. Davitecco.com

- Email : Info@davitecco.com