- Home

- Dai Viet Introdution

- PRODUCTS

- Typical Projects

- Services

- News

- contact

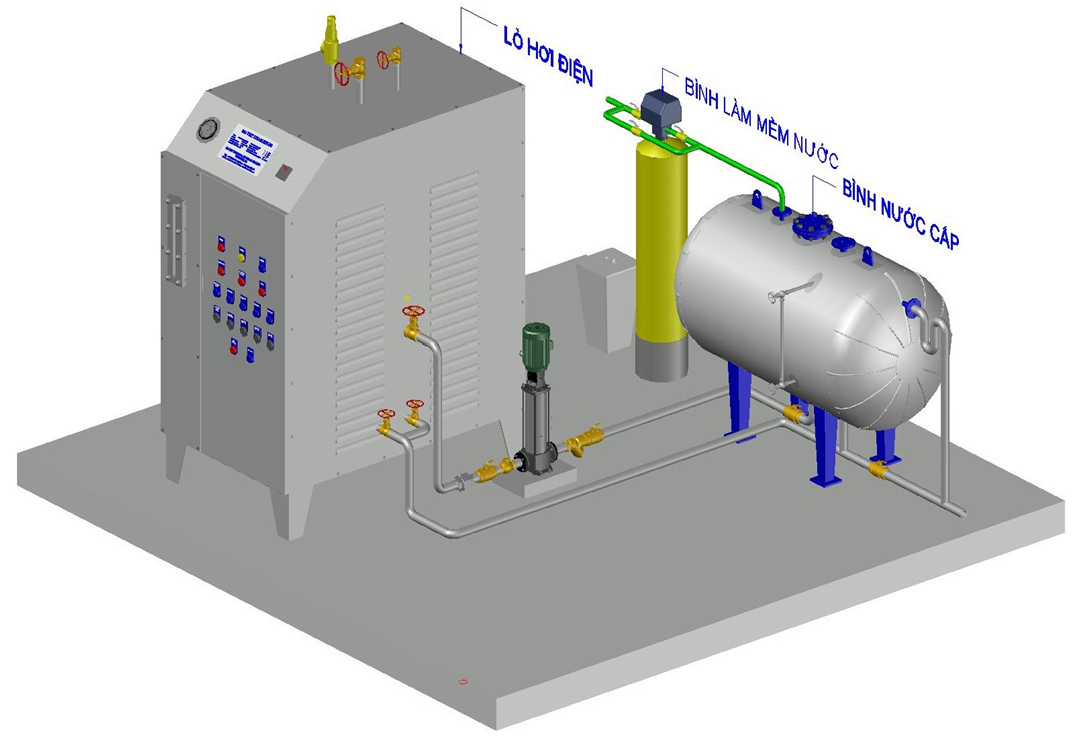

Dai Viet Electric Steam Boiler

Code:The development of industrial electric boilers has become essential to meet today’s environmental challenges. With energy sources for electricity generation growing significantly over the past few decades, authorities in every country are implementing policies to encourage and support a rapid energy transition. Electrically heated industrial boilers are becoming an indispensable tool to meet the twin challenges of energy optimization and decarbonization.

Introduction

Dai Viet electric steam boiler

The development of industrial electric boilers has become essential to meet today’s environmental challenges. With energy sources for electricity generation growing significantly over the past few decades, authorities in every country are implementing policies to encourage and support a rapid energy transition. Electrically heated industrial boilers are becoming an indispensable tool to meet the twin challenges of energy optimization and decarbonization.

By using electricity as an energy source instead of fossil fuels, electric boilers do not emit CO2 at the point of use. Easy to install, they deliver high efficiency with easy operation.

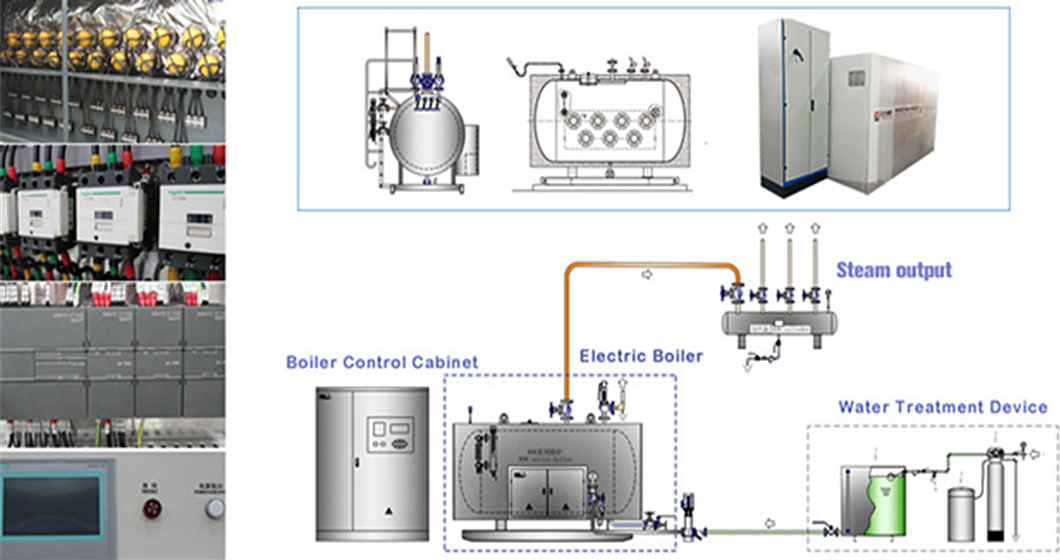

Operating Principle

Electric boilers convert electricity into heat to produce steam. All input electrical energy is converted into heat energy, providing near 100% efficiency with fast start-up and precise control of steam pressure.

Advantages of electric boilers

- 100% efficiency

- No emissions at user's site

- Accurate steam pressure control

- Simple installation and operation

- Easy to inspect according to regulations

- Low maintenance and service costs

- Sturdy structure for long-term operation

- Easy user interface with central control system.

- Reduce operating costs with unmanned control system

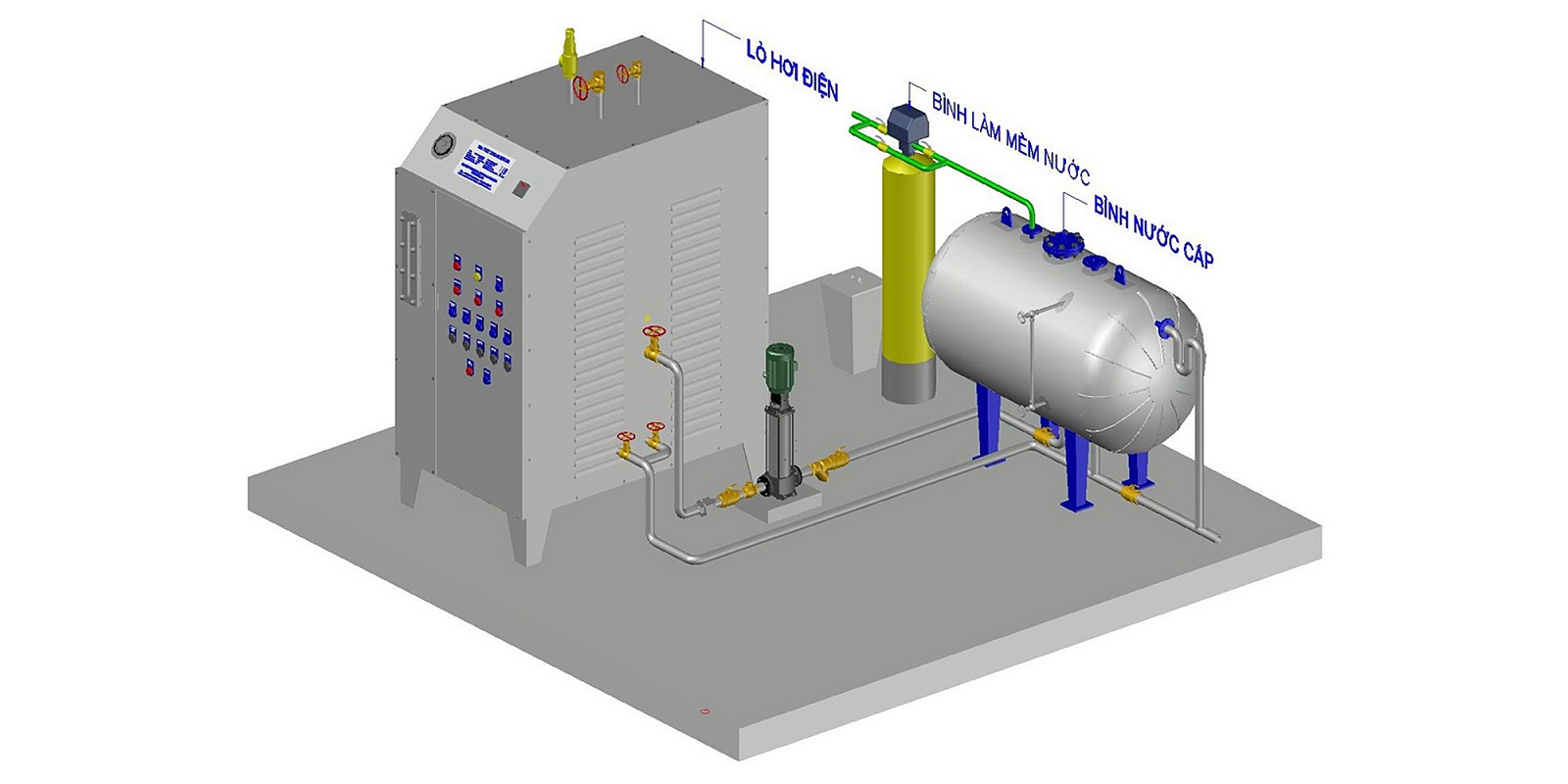

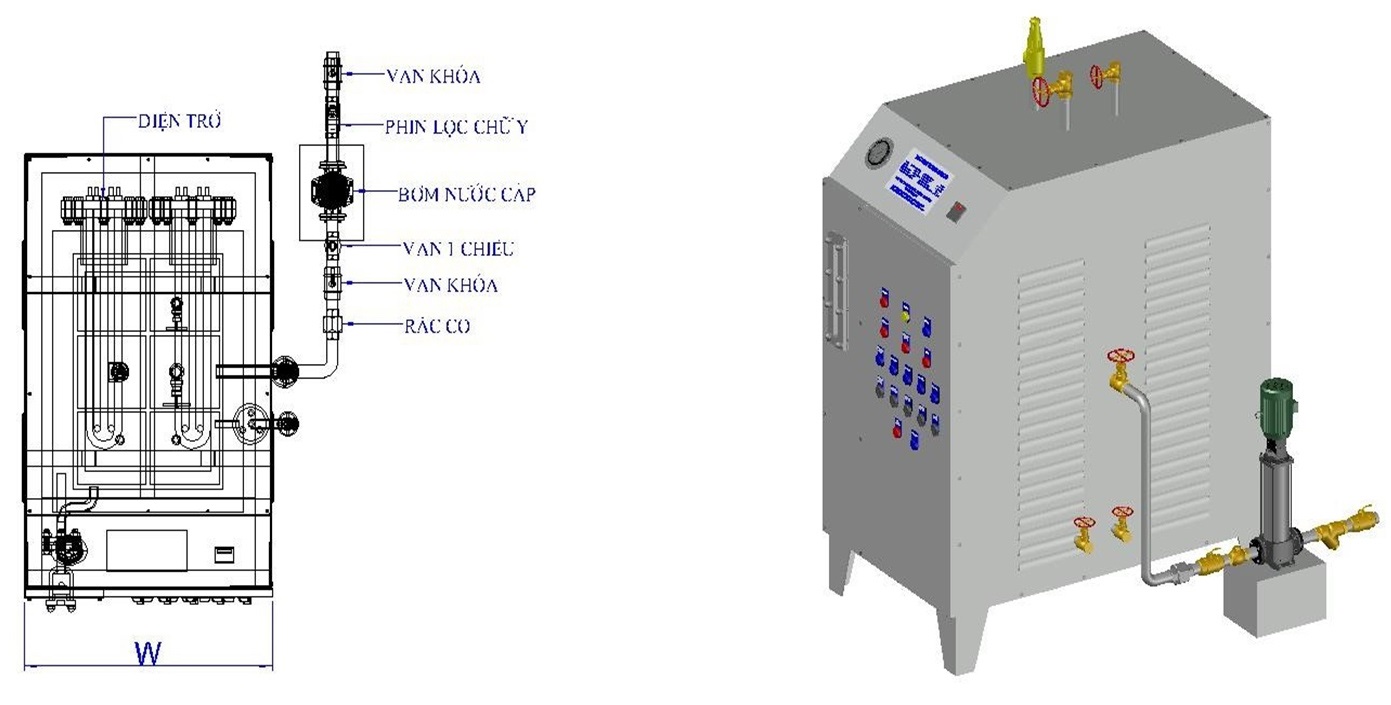

- DAI VIET vertical electric boiler, is a steam electric boiler with simple structure, quick start, one-button start, small area, thermal efficiency up to 100%.

- Small size, Light weight, Easy to install, Mobile, No pollution.

- Double safety guarantee, Electric steam generation, Safety guarantee.

Why choose electric boilers

Electric boilers are very popular because they are emission-free and pollution-free. Many owners consider the investment cost of electric boilers when some factories plan to replace old boilers or increase the production scale of the factory.

The design of electric boilers is a type of boiler that provides water, self-control, steam generation system and safety protection. It uses electricity to generate heat and generate steam at a certain pressure. With the advantages of being fully automatic (convenient to use), non-polluting, simple installation, easy to operate, high efficiency, new modern design, and easy to move. In a place where the electricity price is cheap locally, buying an electric boiler will be a great choice.

Small capacity, small occupation area, quick start with just one button. Suitable for small steam capacity used in industry.

How Electric Boilers Work and Compare Their Advantages with Other Fuel-Fired Boilers

An electric boiler is a type of boiler in which steam is generated using electricity, rather than through the combustion of a fuel source. Such boilers are used to generate steam for process purposes in many locations, such as laundries, food processing plants, and hospitals. Although they are more expensive to operate than gas or oil boilers, they are popular because of their simplicity and ease of use. Because of the large current they require, they are usually run on three-phase power. They convert electrical energy into thermal energy with an efficiency close to 100%, but the overall thermal efficiency varies, depending on the efficiency of the electricity generated.

The process of generating steam using an electric boiler is quite simple. Electricity is passed through a heating element that acts as a resistor to generate heat through the resistor. Water from the system or tank is then run through or near this heating element in a pipe or tank, heating the water to the appropriate temperature, then making the water hot enough to boil and become saturated steam, at which point the saturated steam is transported to wherever it is needed through steam pipes exiting the body of the electric boiler. Electric steam boilers operate in a very similar way to hot water boilers except for the water heating element. Some experts who work with boilers on a daily basis feel that electric boilers are actually superior to fuel boilers in some aspects. These experts say that using an electric boiler can actually be cheaper than using a fuel boiler, and can also be more environmentally friendly. Electric boilers also require less installation equipment than traditional boilers, reducing the high installation costs that come with fuel boilers. Electric boilers can be suitable for smaller areas due to the way they are built and do not require the required components that fuel-fired boilers require to operate.

Traditional fuel-fired boilers often require a variety of components to operate successfully. In contrast, electric boilers are relatively simple units. Additionally, because electric boilers do not use complex forms of heat exchange, electric boilers do not present many of the potential hazards that fuel-fired boilers do. Electric boilers are also often easier to maintain because they do not require tube replacement, which fuel-fired boilers often require due to soot and fuel residue, or any of the combustion maintenance required for fuel-fired boilers. Electric boilers also have a smaller carbon footprint than their traditional cousins, fuel-fired steam boilers, and generally take up less space, making them a good choice for smaller boiler operations.

Some other benefits that can be considered are sustainability, due to low maintenance requirements; marketing, due to the idea that “green” is better and safer, as it is not as dangerous to operate as a traditional fire boiler. Electric steam boilers are more efficient than fire boilers because they require less energy to operate at full capacity. This is because there is less energy lost when the heat transfer from the heating element to the water takes place, unlike a traditional fire boiler, where a significant amount of energy is lost from the airflow needed to supply oxygen to the fire. However, if the electricity is generated by a thermal power plant, the overall system is less efficient than a fire boiler because the power plant is less efficient. Therefore, using an electric boiler can actually consume more fuel than if the electricity was generated by burning fuel. Electric boilers are easier to market (than fire boilers) to people using them for small applications, as it can be sold on the idea that it is "green" and therefore much better for the environment than buying and operating a fire boiler.

Disadvantages

Sometimes some experts look down on electric boilers for a variety of reasons. These reasons stem from the fact that Electricity is very expensive and with electricity prices expected to rise, the use of electricity in an electric boiler will be very expensive. While it is argued that in the event of a power outage or local power failure, the boiler will be unusable (compared to a gas boiler), the reality is that both systems require an external power source to run, such as to operate and control pumps and valves.

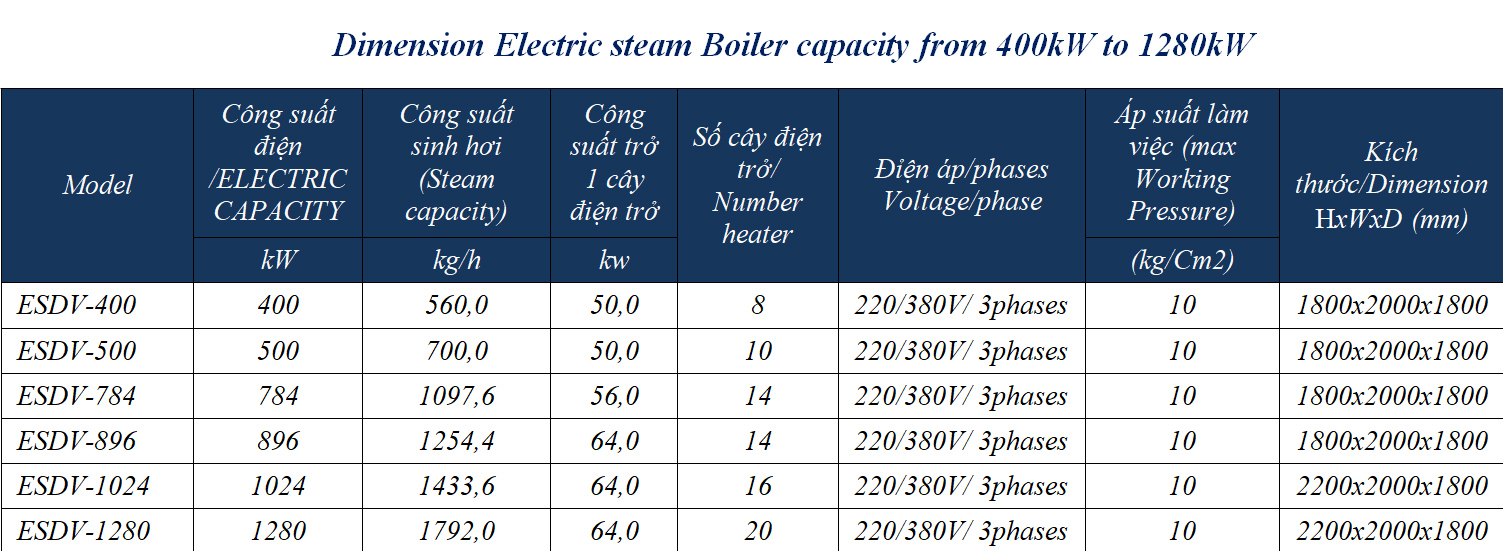

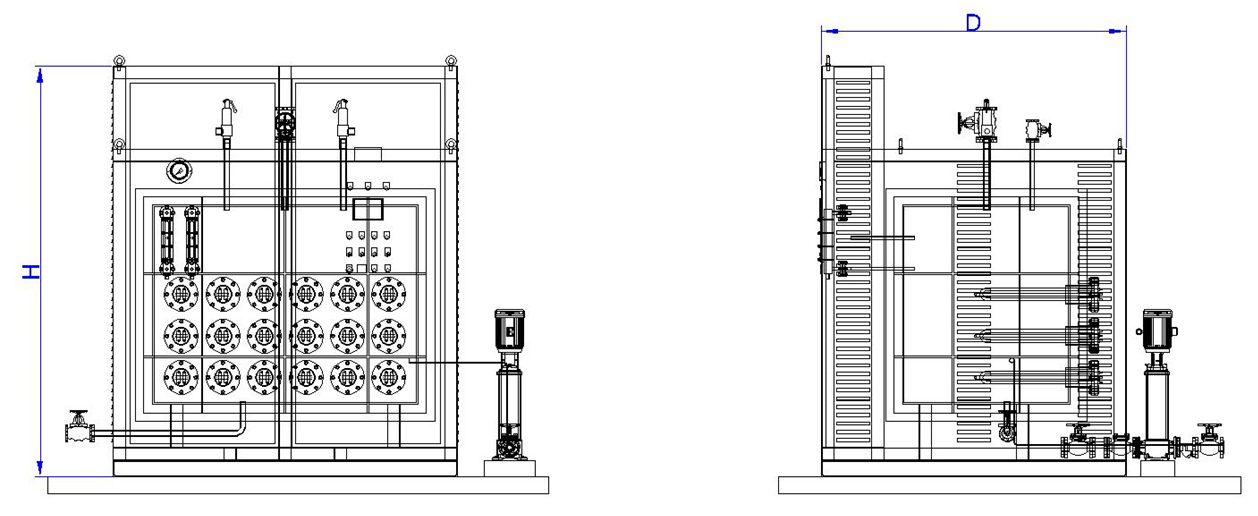

TECHNICAL SPECIFICATION

DAVITECCO electric boilers are very strict about safety. The safety factor is strictly tested before leaving the factory. Electric boilers include the following types:

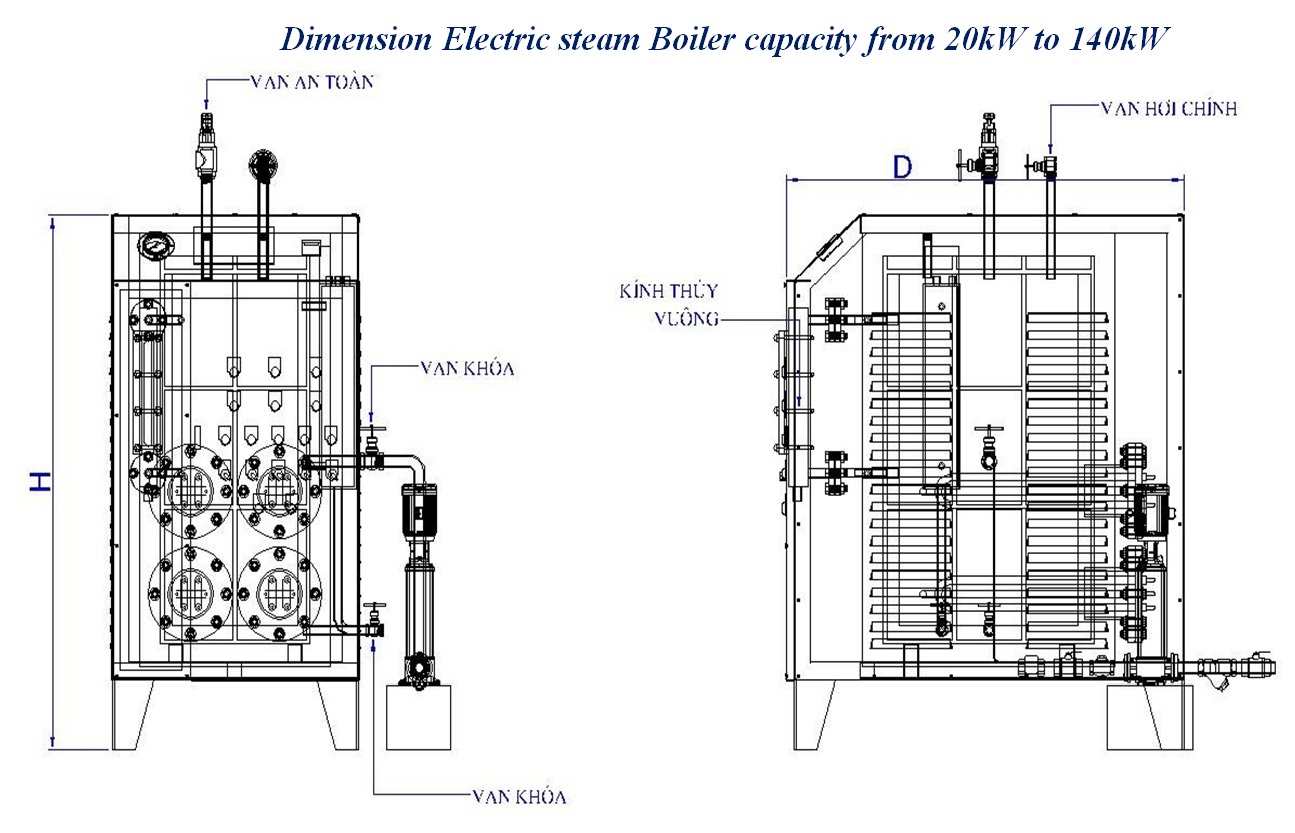

A - ELECTRIC BOILER WITH CAPACITY UP TO 300KW ( LÒ HƠI ĐIỆN CÔNG SUẤT ĐẾN 300KW )

.jpg)

Note: DAVITECCO electric boilers are designed with capacity and working pressure according to customer requirements, in addition to the above capacity range.

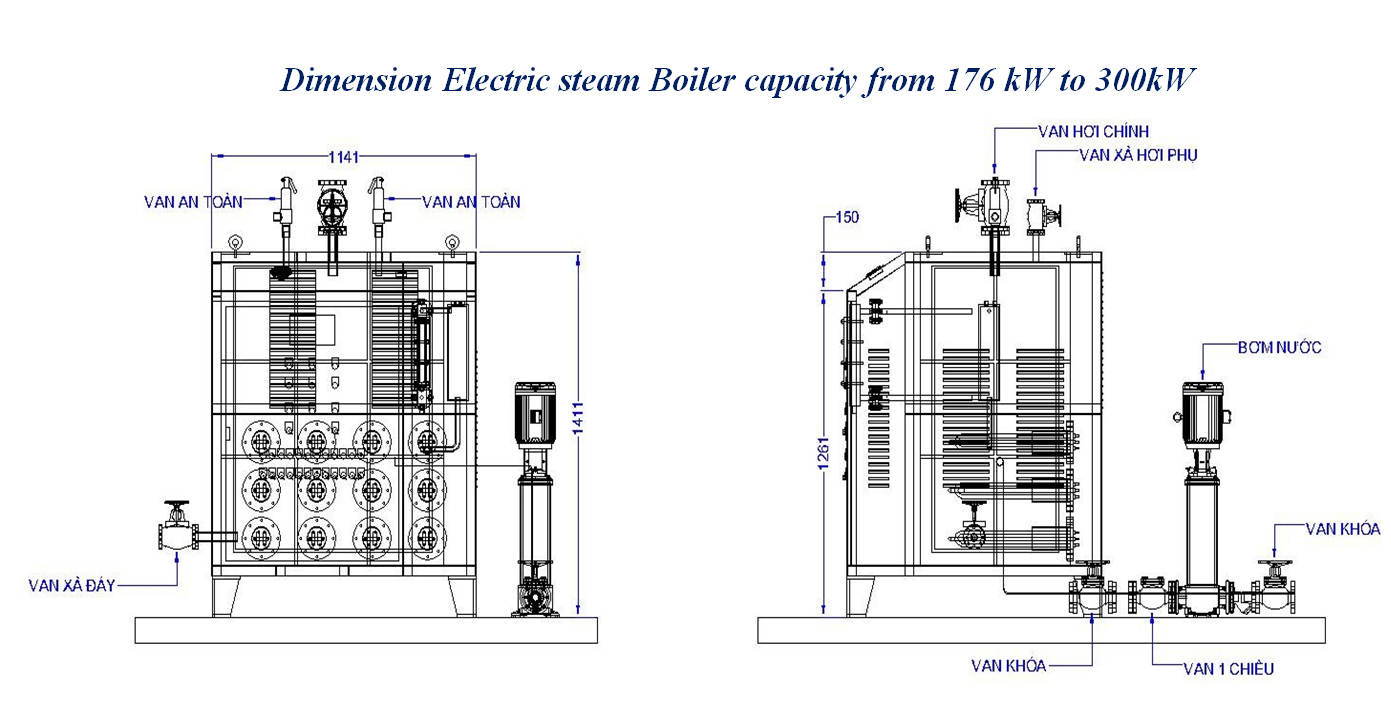

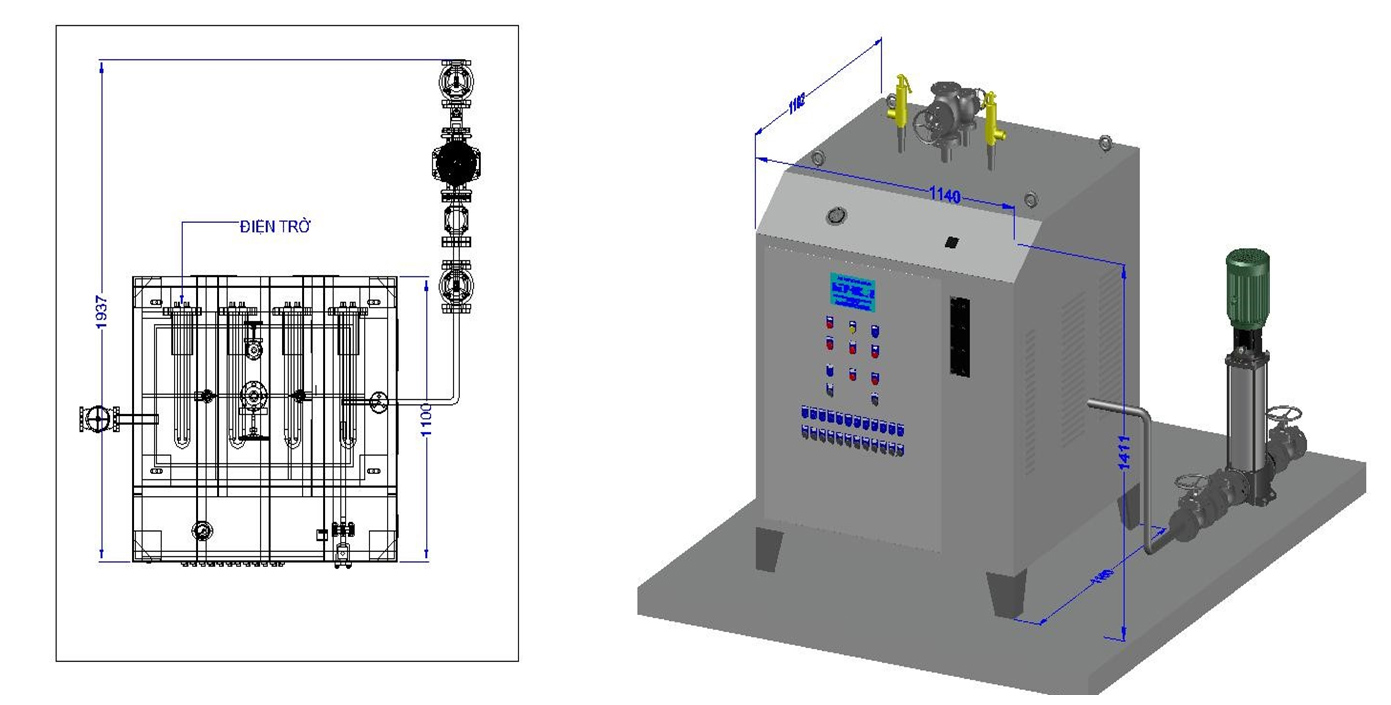

Dimension Electric steam Boiler capacity from 176 kW to 300kW

SAFETY PROTECTION AND CONTROL SYSTEM:

1. Level 1 pressure control: Automatically start and stop at the set pressure using 02 parallel pressure relays, if one of the 02 is broken, the other will cut off all boiler equipment

2. Level 2 pressure control: If the pressure relays do not work at the set pressure, the safety valve will release the pressure to protect the boiler, also using 02 safety valves to protect, if one is broken, the other will release.

3. Level 3 water level control: The water level control system in the boiler works completely automatically when the water level in the boiler drops to a lower water level than the setting, the water pump will automatically pump water into the boiler until it reaches the set water level and then stop supplying water. In case the water pump does not work to supply water to the boiler, when the water level is too low, the boiler will automatically stop all equipment and alarm the operator.

4. Control the temperature of the boiler body: Use temperature sensors to get signals from the steam temperature in the boiler, when the water is low, the burner still works, causing the steam temperature in the boiler to increase to the temperature setting point, the equipment will automatically cut off all boiler equipment, the alarm bell will ring loudly to notify the operator to handle.

Lò hơi điện Đại Việt chạy bằng lập trình PLC hoặc bấm nút tùy theo yêu cầu cảu khách hàng

DOCUMENTS ACCOMPANYING THE BOILER FOR EACH BOILER:

- 01 Boiler strength calculation sheet.

- 01 Factory release certificate.

- 01 Boiler steel origin certificate

- 02 Electrical circuit diagrams

- 01 Operating manual.

Applications of electric boilers in industry today

Currently, industrial electric boilers are widely used in industries such as: food, beverage, medical, chemical, textile, animal feed, ... to serve human life. Depending on the stage of use.

Applications of electric boilers in the food processing industry

In the food processing industry, industrial boiler manufacturers are used to provide steam to serve the production of canned foods. Industrial cooking

In the textile industry

For the textile industry, industrial boilers are used for dyeing, sizing, drying, weaving. ironing, laundry Depending on many stages, factories will use different heat regimes.

In the paper production industry, rubber processing, wood, basic construction

Currently, most units in these fields often use wood-fired boilers to take advantage of available fuels.

Enterprises use industrial boilers in the paper industry to glue, cook pulp, roll, steam, and dry paper.

Industrial boilers in paper production

In the rubber processing industry, boilers are used for steaming and drying to serve factories in the processing stage of shells and inner tubes of bicycles, motorbikes, and cars.

Industrial boilers in rubber processing

In the wood processing industry, boilers are used for pressing boards, maintaining, fumigating, drying wood, and oiling wooden poles.

Industrial boilers in wood processing

Finally, enterprises now use industrial boilers in the construction industry to quickly dry concrete structures. Thereby speeding up the production cycle and increasing productivity.

Commonly used in the service industry

The application of industrial boilers in the service industry is used for heating, steaming, cleaning eating and cooking utensils. This shows that boilers play an extremely important role, an indispensable part of daily life.

Using industrial boilers to clean cooking utensils

Application of boilers in daily life

Not only in industry, medicine, transportation, now boilers are also applied in daily life activities.

The design of civil boilers is quite compact, less cumbersome than industrial boiler systems. Some applications of boilers can be mentioned as:

• Steam boilers for making cakes (rice paper, rice rolls, rice paper, vermicelli, etc.)

• Heating: Hot steam flows through the pipe system and radiates heat throughout the house, helping to warm the house.

• Pressure cooker: It can be said that this is the original type of boiler. The operating mechanism of a pressure cooker is: Sealed, preventing steam from leaking out - Steam is boiled before being released into the environment. The temperature of the steam will be used to stay and simmer the cooking ingredients.

.jpg)

Dai Viet electric boiler

DAI VIET TRADING & TECHNICAL SERVICES COMPANY ., Ltd

Tel: (+84)2363.615226/ (+84)916860231

Web: www.Davitecco.vn