- Home

- Dai Viet Introdution

- PRODUCTS

- Typical Projects

- Services

- News

- contact

Thermal oil furnace using DO, FO, GAS . oil

Code:Heat carrier oil furnace is a thermal device. Using fuel (oil, gas, ...) burned in the combustion chamber produces high-temperature combustion products (smoke). Used in industry

PRODUCT INTRODUCTION

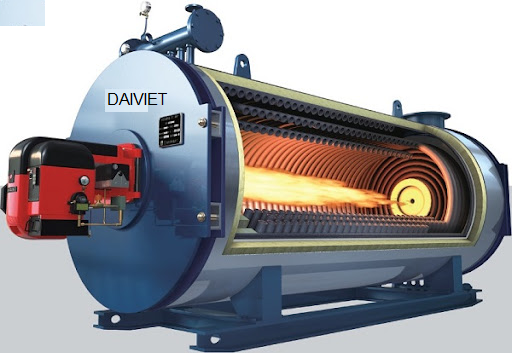

DAI VIET THERMAL OIL BOILER, FUEL DO, FO, GAS

Product description

Thermal oil boiler is a thermal equipment. The fuel (oil, gas, coal, biomass…) is burned in the combustion chamber creating a high temperature combustion product (smoke). Smoke transfers heat to the oil transfer that moves inside the coil through convection and radiation. After receiving heat, oil transfer temperature can be increased to 320oC, that can use for industrial purposes such as: Chemical industry, food industry, paper industry, pharmaceutical industry, ruber industry, rice mill industry, asphalt industry…

Application

.jpg)

|

No. |

Industry |

Useage |

|

1 |

Chemical industry |

Polymerization industry, oil industry, reaction tank, distillation, enrichment, oil chemical industry, concentration |

|

2 |

Plastic industry |

Plastic foam and squeeze to finalize the design |

|

3 |

Textile industry |

Dyeing machine, and the dry room, high temperature machine,roller |

|

4 |

Ruber industry |

Cooking, dry, and vegetable oil refining |

|

5 |

Wood industry |

Heating to finalize the design of chipboard, sandwich plate, fiber |

|

6 |

Paper industry |

Multi-layer cardboard of packed carton box,dying and desiccation |

|

7 |

Others |

Heating of metal electroplating slot, coating condensation, rice mill industry, pharmaceutical industry, asphalt industry, air conditioning… |

Advantages of thermal oil boiler:

1) Thermal oil boilers are cheaper to operate and maintain than stram boilers;

2) Operating a thermal oil boiler is simpler and safer than a steam boiler;

3) Due to less corrosion, the service life of the thermal oil boiler is high

4) The temperature of thermal oil transfer can be up to 350oC.

High Quality Assurance

1) DAVITECCO Boiler owns a team of professional design engineer team. Before production, all design drawings will be approved by boiler experts. The production process is supervised by a team of experienced engineers in the field of boiler manufacturing. Boilers are manufactured when they reach the designed capacity and ensure safety according to Vietnamese standards.

2) To ensure quality assurance, all the materials are used to make the boiler must have a certificate of origin. Qualified materials are put in storage and used for the manufacture of boiler system.

3) To ensure the welding quality, there a professional welding team, including more than 10 senior welders. The welding materials are stored under constant temperature and humidity, to ensure the welding material quality.

4) Nondestructive testing will be done to ensure the welding quality, by using x-ray detection, ultrasonic flaw detection, magnetic test, or penetration test, etc.

5) Hydrostatic testing will be carried out for durable and leak tests of boilers. The test pressure is 1.5 times the design pressure. The testing process is directed by the experts of the pressure equipment testing center. The test results serve as a basis for granting inspection documents for boilers.

Professional Installation and After-sale Team

1) Professional engineer installation team offer the door to door installation and after sale service. The boilers will operate smoothly and safety, and you will get our products without worries.

2) 24 hours hot-line to solve your problems, and offer the professional technical supports and after sale service in time to all over the Viet Nam.

Technical Parameters of thermal oil boiler:

.jpeg)

Contact information :

- DAI VIET TRADING & TECHNICAL SERVICSE COMPANY.,LTD

- ADDRESS : 563 NÚI THÀNH STREET – VIET NAM

- TEL : +84.2363.615226

- Web 2 : www. davitecco.com

- Web 2 : www. davitecco.vn

- Email : Info@davitecco.com